In industrial applications, durability is a key factor in ensuring efficiency and longevity. One of the most reliable ways to enhance durability is through the use of composite lining systems. These systems are engineered to provide unmatched chemical resistance and strength, protecting equipment and surfaces from the harshest environments. In this article, we will explore the benefits, applications, and long-term value of investing in an advanced composite lining system.

What is a Composite Lining System?

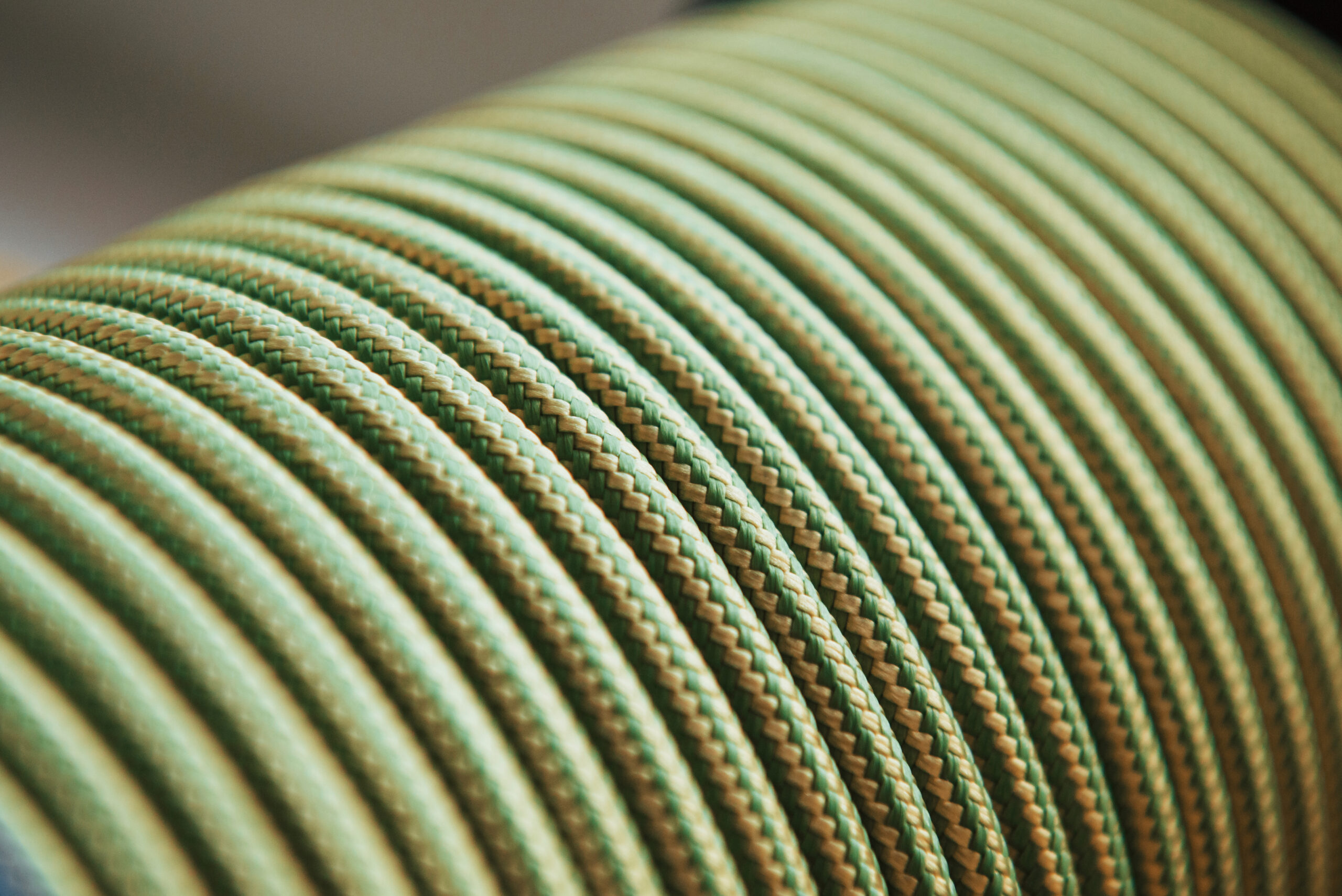

A composite lining system combines different materials, typically resins, reinforcements, and other components, to form a protective barrier. This barrier shields equipment and surfaces from corrosive chemicals, abrasion, and extreme temperatures, making it a highly durable and versatile solution for various industries.

Benefits of Composite Lining

- Superior Chemical Resistance

One of the key advantages of composite linings is their ability to withstand exposure to aggressive chemicals, including acids, alkalis, and solvents. This makes them ideal for industries such as chemical processing, pharmaceuticals, and oil and gas, where equipment is regularly exposed to harsh substances. - Enhanced Mechanical Strength

Composite linings offer exceptional mechanical strength, protecting surfaces from wear and tear caused by friction, impact, and abrasion. This increased durability helps extend the lifespan of equipment, reducing the frequency and cost of repairs or replacements. - Thermal Stability

Many composite lining systems are designed to withstand extreme temperatures, making them suitable for applications where temperature fluctuations are common. This thermal stability ensures that the lining maintains its protective properties in both high and low-temperature environments. - Cost-Effective Maintenance

By preventing corrosion and damage, composite linings reduce the need for frequent maintenance and repairs. This leads to lower operational costs and minimizes downtime, allowing businesses to focus on production and profitability. - Lightweight and Flexible

Unlike traditional metal coatings or linings, composite systems are lightweight, reducing the overall weight of equipment and structures. Additionally, their flexibility allows for easier installation on complex shapes and surfaces, offering a seamless protective layer.

Applications of Composite Lining Systems

Composite lining systems are widely used across several industries due to their versatility and reliability. Some of the key applications include:

- Storage Tanks and Pipelines: Composite linings protect tanks and pipelines from corrosive chemicals, ensuring the safe storage and transport of hazardous materials.

- Industrial Reactors: In chemical plants and refineries, reactors lined with composite materials resist corrosion and maintain their structural integrity under extreme conditions.

- Wastewater Treatment Plants: Composite linings provide a protective barrier against the harsh chemicals and abrasion commonly found in wastewater systems.

- Mining Equipment: Mining operations rely on composite linings to protect equipment exposed to abrasive materials and chemical-laden environments.

Long-Term Value and Sustainability

Investing in a composite lining system offers significant long-term value. Not only do these linings provide enhanced protection, but they also contribute to a sustainable operation by reducing material waste and energy consumption associated with frequent repairs and replacements. Additionally, the durability of composite linings supports environmental compliance by preventing leaks and contamination in critical industrial processes.

Conclusion

In conclusion, advanced composite lining systems are an excellent solution for industries seeking to boost durability and protect their equipment from chemical and physical damage. With benefits such as superior chemical resistance, thermal stability, and mechanical strength, these systems provide unmatched protection in some of the harshest industrial environments. By investing in composite linings, businesses can achieve long-term cost savings, improved safety, and sustainable operations.

Optimize your industrial processes today with composite lining systems—a smart, durable, and cost-effective solution!