Introduction

In industrial applications where durability and reliability are paramount, perfluoroalkoxy emerges as a standout material. Known for its superior chemical resistance and high performance, PFA is a preferred choice in industries like chemical processing, pharmaceuticals, electronics, and more. This article explores the unique properties of PFA, why it is valued across various sectors, and how it can enhance operational efficiency and safety.

What is Perfluoroalkoxy (PFA)?

Perfluoroalkoxy is a type of fluoropolymer that combines the non-stick properties of PTFE (Polytetrafluoroethylene) with improved flexibility and processing capabilities. It is a thermoplastic with high performance, making it suitable for demanding applications that require resistance to chemicals and extreme temperatures. PFA offers a smooth, non-reactive surface that is ideal for handling aggressive substances without the risk of corrosion or degradation.

working but not at its full capacity. This can cause sluggish movements, decreased power output, and erratic behavior in machinery.

Key Benefits of PFA: Why It Outperforms Other Materials

Unmatched Chemical Resistance:

PFA stands out due to its ability to resist nearly all chemicals, including highly corrosive acids, alkalis, and organic solvents. This makes it a top choice for chemical processing equipment, where maintaining material integrity is crucial. Unlike traditional materials that may corrode or weaken over time, PFA remains inert, ensuring a longer lifespan for critical components.

High-Temperature Stability:

PFA is known for its ability to withstand temperatures up to 260°C (500°F), making it suitable for high-temperature applications. This stability ensures that PFA-lined pipes, fittings, and other components can perform consistently even under extreme heat conditions, reducing the risk of failure or damage.

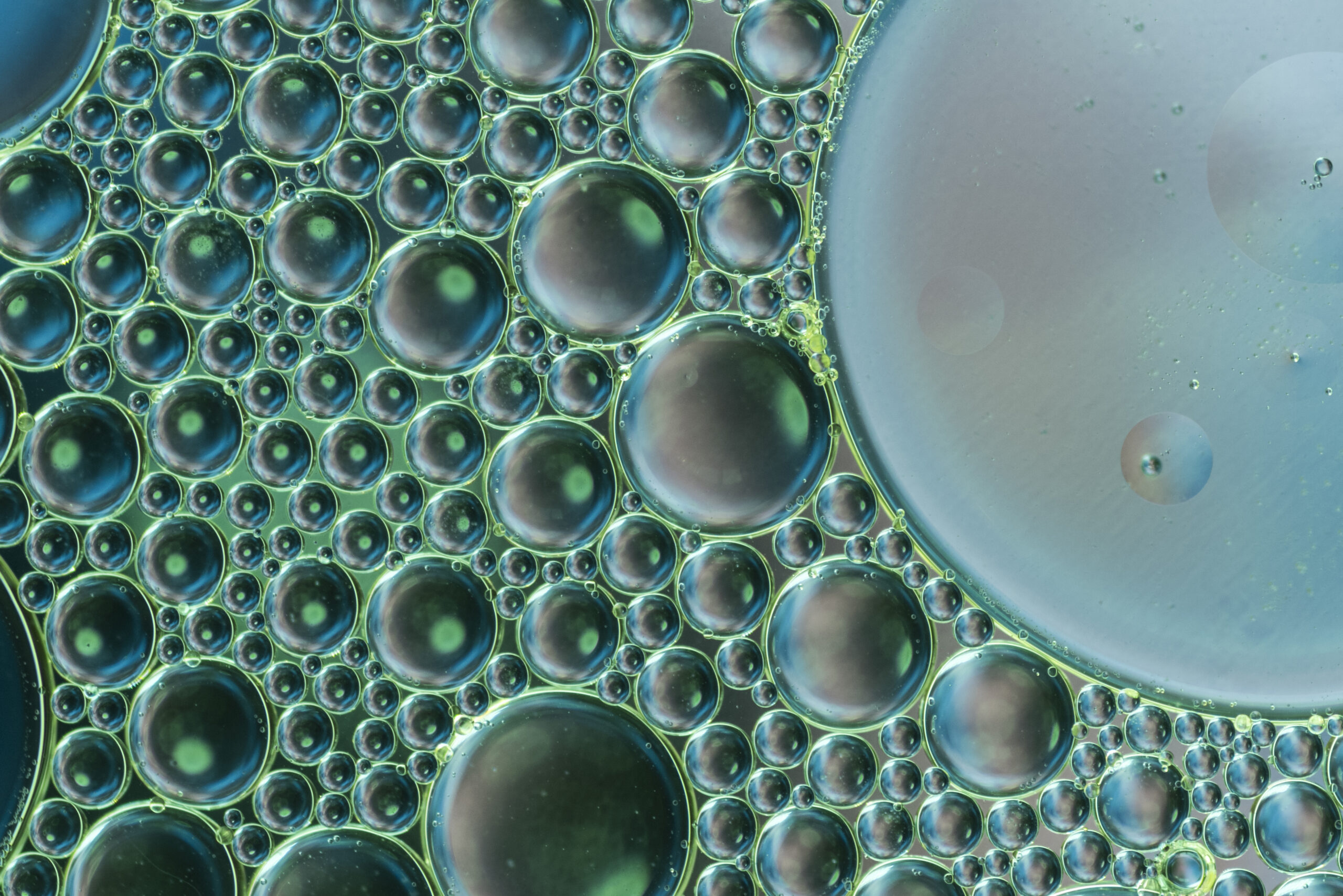

Non-Stick Surface:

One of the most advantageous properties of PFA is its non-stick nature. The smooth surface prevents material buildup and makes cleaning easy, which is especially beneficial in industries like food processing and pharmaceutical manufacturing. This property also helps maintain the purity of substances, preventing contamination in processes that require the highest levels of cleanliness.

Durability and Longevity:

PFA is highly durable and resistant to wear and tear. This makes it a cost-effective solution for industries looking to reduce maintenance expenses and extend the lifespan of their equipment. By using PFA-lined components, companies can significantly cut down on the need for replacements, leading to lower overall costs.

Electrical Insulation:

Beyond chemical and thermal properties, PFA offers excellent electrical insulation. Its high dielectric strength makes it suitable for applications in the electronics industry, such as wire insulation and protective coatings for sensitive electronic components.

Applications of PFA in Key Industries

Chemical Processing:

The chemical industry often involves handling highly reactive substances that can corrode traditional materials. PFA-lined pipes, valves, and storage tanks ensure that these chemicals are transported safely, minimizing the risk of leaks and contamination. PFA’s ability to withstand both high temperatures and aggressive chemicals makes it a reliable choice in this sector.

Pharmaceuticals and Biotechnology:

The non-reactive nature of PFA makes it ideal for pharmaceutical applications where maintaining purity is essential. It is used in equipment that comes into contact with active pharmaceutical ingredients (APIs) and biological substances. PFA-lined components help prevent reactions that could compromise the quality of medicines or research samples.

Food and Beverage Industry:

In food processing, hygiene and safety are top priorities. PFA’s non-stick surface helps prevent residue buildup in piping systems, ensuring a clean environment for the production and transport of food products. Additionally, PFA can handle the high temperatures involved in processes like pasteurization, making it a valuable material for this industry.

Semiconductor Manufacturing:

The production of semiconductors requires ultra-high-purity chemicals and strict contamination control. PFA’s smooth, inert surface prevents impurities from leaching into the production environment, ensuring the quality of microchips and other electronic components. Its use in chemical delivery systems and process chambers helps maintain the precision and purity required in semiconductor fabrication.

Why Choose PFA for Your Industrial Needs?

Cost-Effectiveness Over Time:

While the initial cost of PFA components might be higher than other materials, its long-term benefits make it a cost-effective solution. The reduced need for replacements, lower maintenance costs, and increased equipment lifespan all contribute to substantial savings over time.

Versatility Across Applications:

PFA’s adaptability allows it to be used in a variety of applications, from coatings to molded parts and films. It can be applied as a lining to protect metal surfaces or used as standalone components in systems that require both chemical resistance and thermal stability.

Enhanced Safety and Compliance:

In industries like pharmaceuticals and food processing, compliance with safety standards is critical. PFA helps meet these requirements due to its non-toxicity and ability to maintain a sterile environment. Using PFA ensures that your operations remain safe and compliant with industry regulations.

How to Maximize the Benefits of PFA

To fully leverage the advantages of Perfluoroalkoxy (PFA), it’s essential to choose the right specifications for your needs. Here are a few tips:

Select the Appropriate Lining Thickness: The thickness of the PFA lining can affect its durability and performance. Consult with experts to determine the best thickness for your application.

Perform Regular Maintenance: Although PFA is highly resistant, regular inspections can help identify wear or damage early, ensuring that your system continues to function efficiently.

Partner with Experienced Suppliers: Quality matters when it comes to PFA components. Partnering with reputable suppliers ensures that you receive high-quality products tailored to your specific needs.

Conclusion: PFA – The Ideal Material for Tough Conditions

Perfluoroalkoxy (PFA) is more than just a high-performance material; it is a strategic investment for industries that demand chemical resistance and high-temperature stability. Whether you’re dealing with aggressive chemicals, extreme temperatures, or environments that require stringent purity, PFA is the solution that can enhance the efficiency and reliability of your operations. Embrace the power of PFA and unlock new possibilities for your industrial processes, ensuring safety, durability, and long-term success.