High-density polyethylene (HDPE) pipes are widely used in various industries due to their strength, durability, and flexibility. These pipes transport various substances, such as water, gas, and chemicals. However, despite their many advantages, HDPE pipes can still rupture, which can cause serious safety concerns and financial losses.

Ruptures in HDPE pipes can be caused by various factors, such as manufacturing defects, installation errors, external forces, and corrosion. To prevent these ruptures, it’s essential to take proactive measures and ensure the pipes are installed and maintained correctly.

You may also interested in our blog: Pipeline Pigging: What Is It And How Does It Work?

In this blog, we’ll explore the causes of HDPE pipe ruptures and provide steps to prevent them from happening. We’ll also discuss what to do in case of a pipe rupture and the options for repair or replacement.

Causes of HDPE Pipe Rupturing

Several factors can cause HDPE pipe rupturing. Some of the most common causes are discussed below:

1. Installation errors

Improper installation practices, such as incorrect alignment, incorrect fusion, or insufficient support of the pipe, can create stresses that may cause HDPE pipes to fail. For instance, if a pipe is not adequately supported or buried too shallowly, it can experience excessive bending, leading to premature failure.

2. Chemical degradation

Some chemicals, such as chlorine, can cause HDPE pipes to degrade, leading to cracks and eventual rupturing. This is especially true in applications such as chemical processing plants, where the pipes are exposed to harsh chemicals.

3. Thermal degradation

Exposure to high temperatures can also cause HDPE pipes to fail. The material can become brittle when exposed to high temperatures, and the pipe can crack or break.

4. Mechanical damage

External forces, such as machinery or vehicular traffic impacts, can also damage HDPE pipes. Additionally, the pipes can be inadvertently damaged during excavation or other construction work.

5. Fatigue failure

Over time, repeated stresses and strains can cause fatigue failure, resulting in rupturing. This type of failure can occur in areas where the pipe is subjected to frequent changes in pressure or where it experiences vibrations.

6. Manufacturing defects

Occasionally, HDPE pipes may have manufacturing defects that can cause premature failure. Such defects may include uneven wall thickness, surface roughness, or incorrect fusion.

Signs of HDPE pipe rupture

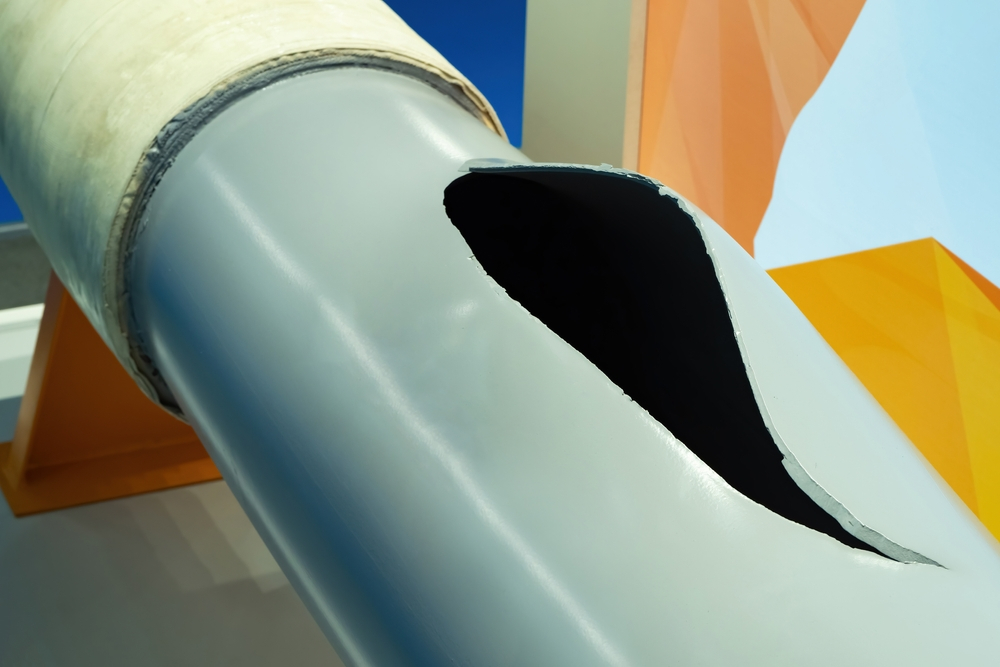

1. Visible damage or cracks

Visible damage or cracks on the surface of an HDPE pipe indicate that the pipe has ruptured. This can occur due to various factors, including improper installation, external forces such as soil movement or impact, or manufacturing defects.

Visible damage or cracks may appear as a visible split, fracture, or hole on the surface of the pipe. Regular inspections of HDPE pipes can help identify visible damage or cracks before they become more severe and lead to a complete rupture.

2. Loss of pressure or flow rate

A sudden drop in pressure or flow rate can indicate an HDPE pipe rupture. This can occur due to a pipe’s integrity loss, which can cause leaks or blockages that prevent water from flowing smoothly.

Monitoring pressure and flow rate regularly can help detect a potential rupture early on and prevent further damage or contamination.

3. Changes in water quality or color

Changes in water quality or color can also indicate an HDPE pipeline bursting. If a pipe ruptures, it can contaminate the water supply, resulting in changes in color, odor, or taste. The water may also contain visible debris, sediment, or discoloration. Monitoring water quality regularly can help detect a potential rupture early on and prevent further water supply contamination.

How to Prevent HDPE Pipeline Bursting?

1. Ensure Proper Installation

Proper installation is critical to the longevity and safety of HDPE pipes. Follow the manufacturer’s instructions carefully and ensure that trained and experienced professionals perform the installation. Some installation best practices include:

- Properly aligning the pipes

- Ensuring the pipes are supported adequately

- Using the correct fittings and connectors

- Maintaining proper fusion and welding temperatures

- Performing quality control checks during and after installation

2. Regularly Inspect the Pipes

Regular inspections can help you identify potential problems before they turn into ruptures. Inspect the pipes for signs of wear and tear, such as cracks, dents, or discoloration. Additionally, check the joints and connections for leaks and make sure they are tight.

3. Perform Maintenance and Repairs

Regular maintenance and repairs can keep your HDPE pipes in good condition. Some maintenance tasks include:

- Cleaning the pipes

- Flushing the pipes

- Repairing leaks or cracks

- Replacing damaged sections of pipe

- Updating connections and fittings

4. Monitor Pressure and Temperature

Monitoring the pressure and temperature of your HDPE pipes can help you identify potential issues before they cause a rupture. Ensure the pipes operate within their specified temperature and pressure ranges, and take corrective action if necessary.

5. Avoid Chemical Exposure

Some chemicals can cause damage to HDPE pipes and increase the risk of ruptures. Ensure the pipes are not exposed to chemicals incompatible with HDPE, such as gasoline, diesel fuel, and solvents.

6. Use the Correct HDPE Pipe for the Job

Make sure you are using the correct HDPE pipe for the job. Different applications require different types of HDPE pipes, so consult an expert to ensure you use the suitable pipe for your specific needs. Using the wrong pipe can increase the risk of ruptures and other problems.

See a detailed comparison on PE Vs HDPE Piping

Conclusion

Preventing HDPE pipeline bursting is crucial to ensure the longevity and functionality of the pipe. It is essential to be aware of the signs of pipe ruptures and respond promptly in case of a rupture to minimize damage and ensure a timely repair. With these measures, HDPE pipes can provide reliable and long-lasting service for various applications.